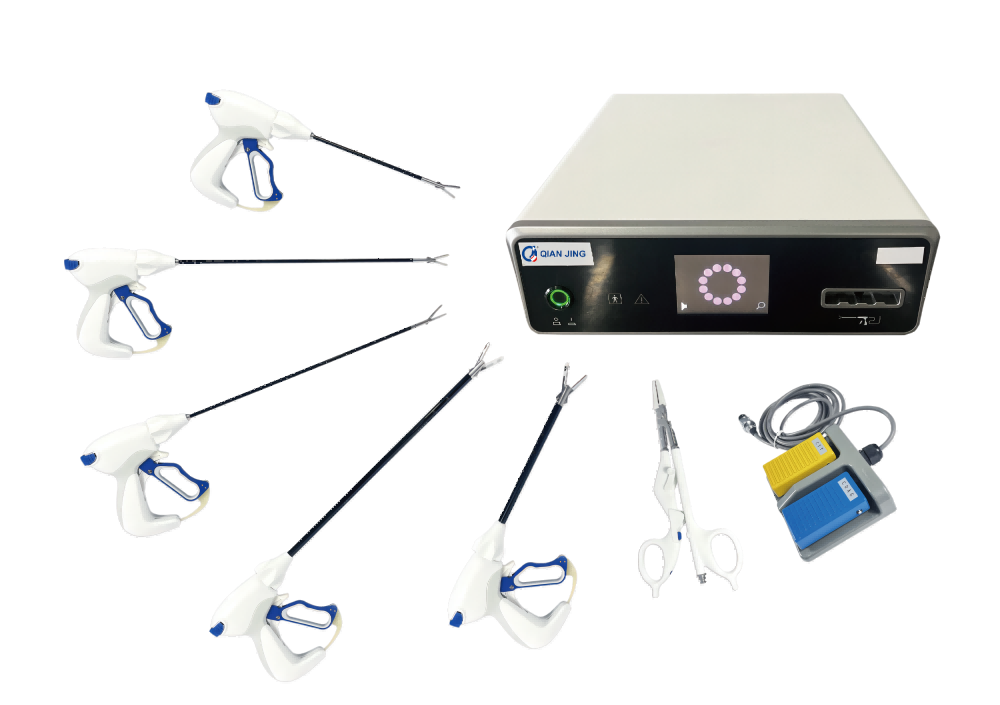

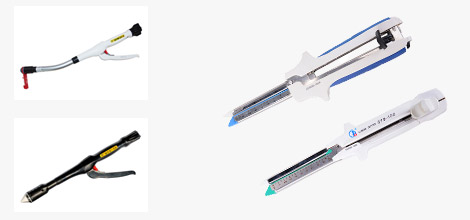

endoscopic linear stapler and nail bin, nail bin processing

The endoscopic linear stapler is a device used in medicine as an alternative to manual suturing. The main working principle is to dissociate or anastomose tissue using titanium staples, similar to a stapler. Depending on the scope of application, they are mainly divided into skin anastomoses, circular anastomoses for the digestive tract (esophagus, gastrointestinal, etc.), rectal anastomoses, circular hemorrhoid anastomoses, circumcision anastomoses, vascular anastomoses, hernia anastomoses, and pulmonary excision sutures.

First of all, what is a stapled position?

The staple compartment is one of the core parts of the endoscopic linear stapler and is very demanding. It carries the pushing staple piece, and when the instrument is working, as the pushing staple slide is pushed, it drives the pushing staple piece to move in the staple compartment hole, and the pushing staple piece pushes the titanium staple against the staple seat, and the titanium staple is closed by pressure to achieve the suturing effect of the tissue. In the whole process, the strength of the nail compartment, the shape of the nail hole characteristics, the consistency of the size and center distance of the nail hole, pushing the nail plate and the nail hole assembly tightness, etc. have high requirements.

Second, the nail bin material selection?

There are two main materials for nail bins, PA66+GF and medical grade LCP, which are the best choice for nail bins because of their reliable fixation, low extraction rate, low complications and strong surgical results. However, this material cools particularly fast and is extremely easy to salivate, this material is not easy to shape, easy to trap air and lack of material, easy to produce burrs, so the structure and precision of the mold requires more.

Once again, the design and production of nail bin mold points of attention.

(1) The design tolerance mark should be reasonable. Especially the dimensional accuracy of the sealing position. Grab the standard shrinkage rate according to the material physical property table of LCP. The design needs to clearly define the fit clearance and tolerance, so as to ensure the smooth fit between the nail pushing piece and the nail bin.

(2) Based on the mold flow analysis and material property table, set the reasonable size of glue inlet and runner. The angle of submerged glue should be controlled well, otherwise the glue inlet point is easy to pull material chips. The location of the bonding line is easy to lack of material, so the exhaust position and depth of exhaust need to be paid attention to. Pay attention to insert splitting to prevent product deformation and sticky mold.

(3) The mold processing process should pay attention to strict tolerance processing, every precision insert involving the fit size needs to ensure that it meets the tolerance of the drawing, quality control should be particularly strict.

(4) According to the mold flow analysis, material characteristics, and the verification of scientific mold testing methods, to develop a reasonable molding process. To ensure the stability of product production.

Nail bin colors are independently distinguished! Different colors of nail bins, corresponding to different uses and sizes.

info@qjmed.com

info@qjmed.com